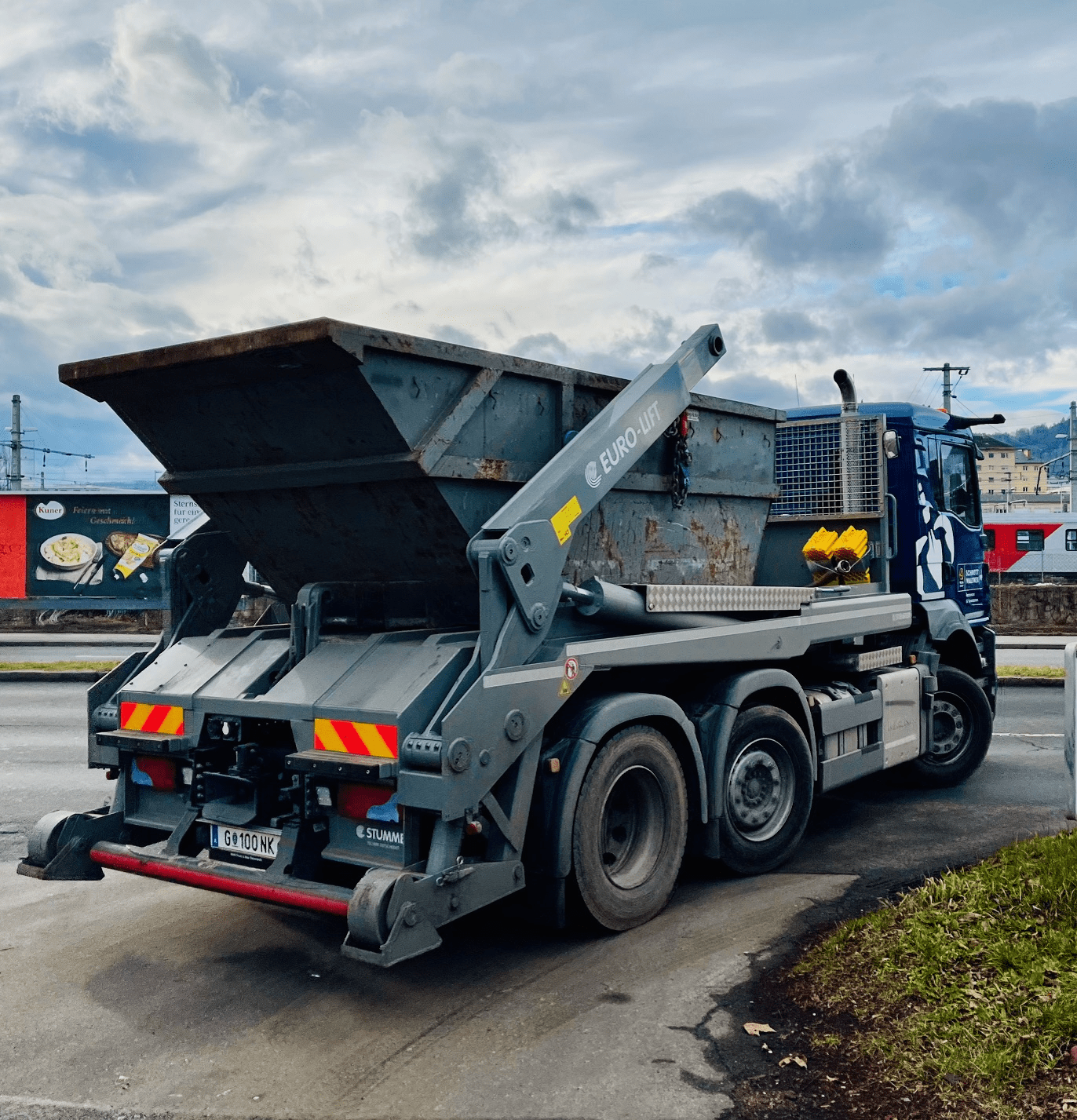

These specially manufactured containers from DARYN are made of robust material from voestalpine Steel & Service Center GmbH – continuing the steel cycle in a particularly meaningful way.

From Scrap to Container – and Back Again

What makes this cycle so special? We supply high-quality scrap materials for melting, which are then refined into durostat® steel at voestalpine Steel & Service Center GmbH through an energy-efficient process. This pre-material is then delivered to DARYN, where it is used to manufacture durable containers for scrap transport. And these are the very containers we use – to transport new scrap efficiently and safely. Thus, the cycle comes full circle: Scrap – Steel Mill – Container – Scrap.

A perfect example of circular economy in action within the REON GROUP – resource-efficient, economically sound, and future-oriented.

durostat® – Built for Harsh Everyday Use

The new containers made from durostat® 400, 450, and 500 are characterized by their exceptional wear resistance and hardness. Especially in the scrap sector, where tons of weight and mechanical stress are exerted on the material daily, this high-performance steel proves to be the ideal companion for everyday operations.

Thanks to its excellent cold-forming properties and reduced sheet thickness with maximum service life, durostat® enables cost-efficient production – without compromising on quality or safety. As a result, the containers are not only durable but also contribute to reducing transport weights and thus emissions.

Together Toward a Sustainable Future

The collaboration between voestalpine Steel & Service Center GmbH, DARYN, and Schrott Waltner impressively demonstrates how smart partnerships create tangible added value – for industry, the environment, and future generations.

With this project, we are making another visible contribution to the circular economy and to sustainable progress in metal recycling.